Frequently Asked Questions

Is the Tear Down Inspection the same as an Overhaul?

Whirl Wind considers our propellers “overhauled” when our tear down inspection procedures are followed. The tear down inspection service should not be incorrectly used synonymously with the term “overhaul” as it is typically understood in aviation. Whirl Wind propellers have unlimited life and therefore are not subject to very high TBO costs like non-serviceable hubs or blades commonly associated with competitors’ propellers. Other than new o-rings, gaskets and some hardware (where applicable), it is very unusual for Whirl Wind propellers to need any other components serviced or replaced.

A well maintained propeller is much less likely to develop problems that may be costly to repair. As its name implies a tear down inspection is complete disassembly, cleaning and visual inspection of the entire propeller assembly; including the blades, spinner assembly, hub and the hub internal components. The primary purpose of the service is to encourage thorough and regular inspections of the propeller, including checking for unusual and / or non-uniform component wear. Whirl Wind designs and manufactures most of the propeller components. The tear down inspection routine provides us with very valuable data on the integrity of our designs. As products mature the recommended tear down inspection intervals are lengthened.

In spite of the more frequent, low cost tear down inspections of a Whirl Wind propeller, it is more cost effective to operate than a typical constant speed propeller and the associated high cost TBO

What is the ball park cost of the Tear Down Inspection and who do I have perform this service?

We recommend returning the propeller to Whirlwind Aviation or one of our authorized service centers for maintenance and service. However, the typical tear down can be performed by most qualified propeller shops and mechanics. We will facilitate such service in every possible way.

For tear down inspection service performed by Whirlwind Aviation please contact us for current rates and shipping estimates.

Why do some of the Whirl Wind propellers have RPM limitations?

Maximum RPM Restriction

The only limitation or restriction on Whirl Wind propellers is the maximum operating RPM, in most cases 2,700 RPM. This is no different than almost all other propeller manufacturers, both experimental and type certified.

The maximum rated RPM of the propeller is something to be taken very seriously and often is not by many pilots. All Whirl Wind propellers are designed with a conservative safety factor based on the maximum RPM of 2,700. The centrifugal blade forces are a squared function of RPM. For example, 2,700 RPM has double the blade centrifugal force than that of 2,000 RPM. Considering this relationship what could be perceived as a small 10% over speed will result in a 21% increase in blade centrifugal force loads. Therefore even a small increase in RPM over the maximum limit will quickly diminish the propeller’s structural safety factor. It is critical to always follow the propeller’s RPM limitations and over speed inspection procedures as detailed in the propeller manufacturer’s manual.

Recommended Non-Continuous Operating Ranges

Whirl Wind follows historical industry standards and recommends that continuous operation between 2,050 - 2,300 RPM and 2,600 - 2,700 RPM be avoided when used on Lycoming and similar four cylinder aircraft engines. (Take off and climb out is not considered continuous operation.)

This recommendation is based on the fact that the four cylinder engines produce torsional vibrations on each power pulse (ignition firing). These vibrations are transferred from the crankshaft through the propeller hub to the propeller blades. Extensive research conducted by propeller manufacturers has demonstrated that these vibrations at engine speeds between 2,000 - 2,300 RPM and greater than 2,600 RPM can cause increased vibratory stresses in the propeller blades and in some cases this torsional vibration can be close to the blade’s resonant frequency. Blades vibrating at their resonant frequencies, or more likely higher order overtones, can be stressed beyond their design limits and could result in limited or complete failure. This phenomenon is a greater concern with aluminum propeller blades because of their lower natural resonant frequency. The natural dampening, high natural resonant frequency and high fatigue resistance of Whirl Wind composite blades makes the likelihood of destructive failure less probable, but to ignore the RPM concerns recognized by the industry would be unwise. Furthermore, flywheel dampening and / or crankshaft counterbalancing can mitigate the torsional vibrations but not eliminate them completely. It is only prudent to avoid operating in these critical RPM ranges whenever possible.

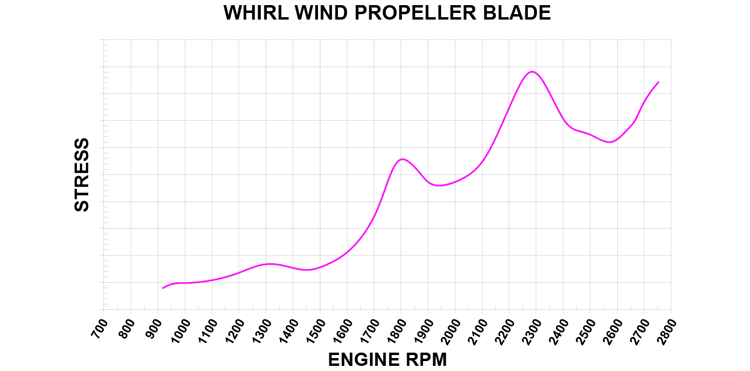

Whirl Wind’s extensive testing and vibration mapping of blade stresses has further proven that this phenomena exits as shown in the following simplified engine RPM verse blade stress graph:

Every propeller is subject to these same conditions and yields similar test results. However, the material and construction of each distinct propeller design reacts differently to these conditions. As noted above, the natural properties of the Whirl Wind carbon fiber blades are much more tolerant of these conditions, and as detailed in the graph, even at the worst case stress scenario of 2,300 RPM the measured stresses on the Whirl Wind blades are significantly lower than our design standard of 50% (safety factor) of the unlimited life cycle strength of the blade material.

Regardless, it is simply safe practice to follow the RPM recommendations. It should also be considered that the propeller is not the only component of the aircraft that experiences these stresses; everything including the prop, engine and airframe are subject to these stresses simultaneously and it is better for all of the equipment to avoid these conditions.

Additionally, many aircraft engines used in kit planes and experimental aircraft undergo aftermarket modifications to increase their performance, essentially making every engine unique. Additional horsepower amplifies the torsional vibrations resulting in even greater stresses on the propeller blades and therefore may increase the likelihood of propeller blade damage. Any review of type certified propellers will show that the certification is always specific to very particular engine (manufacturer / horsepower / ignition) and airframe combinations, and use of the propeller on modified engines or airframes will nullify the certification.

For more information, extensive writing on this subject can easily be found by reviewing aviation books, periodicals and trade publications as well as searching the internet.

My engine is an IO-360 but I have had the horsepower increased. Are there any issues with using the specified Whirl Wind propeller for my aircraft?

Generally no. There should be no problems as long as the correct propeller is selected for the airframe / power plant. We build to engine specifications and approximate spec horsepower. If you have any concerns please address them with a Whirl Wind representative.

What does your propeller price include?

Included in the quoted price you will receive:

- The propeller system

Including finish base coat / clear coat paint. Base price colors are standard white with red tips or black with white tips. Optional customer selected custom colors available for an additional charge..

- Composite Spinner Assembly (including the front and rear bulkheads)

Duratec® primed and ready for paint

- Mounting Hardware

- Operating and Installation Manual

- Shipping container.

The only additional costs you may encounter include the actual shipping costs to your location from Austinburg, Ohio U.S.A. Governors are sold separately.

Can I get custom paint colors on my propeller?

Yes you can. Additional charges will apply depending on how many colors and the complexity of the design. Please contact Whirlwind Aviation for a quote.

We use PPG paints exclusively.

If you would like custom colors on your propeller you must provide accurate PPG paint code numbers shortly after your order is placed. Whirlwind Aviation will not cross paint codes. Computer color matching is available if a sample panel is provided.

Custom paint schemes (multiple colors, exotic stripes, etc.) are available and subject to additional charges. We will quote custom paint schemes upon receipt of the customer’s artwork. Complicated designs may require customer submission of paint masks or stencils.

What type of governor do I need?

You need a hydraulic governor that runs off of the engine oil pressure. For a standard configuration you will need a governor that goes to flat pitch (governor pressure to increase pitch). For aerobatic configurations you will need a governor that goes to coarse pitch in the event of engine oil pressure loss (governor pressure to decrease pitch which will increase engine RPM). You can use any standard manufacturer such as McCauley, Woodward, etc. Or, you can purchase a Jihostroj (Czech Republic) governor directly from Whirlwind Aviation, which is a bit lighter and smaller than any other governor (about 1.5" less than the McCauley).

Note: The 150 and the 151 Series require a governor with a relief pressure of at least 475 psi.

Are any of your propeller systems certified?

No. We currently serve the experimental aircraft market for both aerobatic and sport planes only.

Do you have plans to certify any of your propellers in the future?

We do not have plans in the immediate future to certify any of our current propeller models.

I don't see my engine listed. Do you offer custom propeller system design for other engines?

No, we only manufacture a specific family of propellers for specific engine and aircraft applications. We will be expanding our product offering as time progresses, but we do not take on any custom design work. As soon as we offer a new propeller system for a new engine or aircraft we will announce it on our website.

What are your spinners made out of?

Our spinners are made out of fiberglass and epoxy and come in standard diameters designed to fit most experimental aircraft. Your propeller system will arrive with the spinner in a primer coat and ready to be painted by you.

Note: It is the customer’s responsibility to insure that their required size spinner is specified at time of order. Both the required diameter (to match engine cowl) and distance from the engine flywheel should be verified to avoid fit problems upon propeller installation.

How will my propeller arrive?

Your new propeller will arrive completely assembled and ready to bolt on your airplane. We statically balance the entire system at our shop but it is recommended that you have your system dynamically balanced once it is installed on your airplane. You will also need to paint the spinner which arrives with a base primer coat.

The assembled propeller system is shipped in its own shipping container. The spinner assembly may be shipped in a separate box depending on its size. Two blade propellers ship via UPS. Three and four blade propellers ship LTL road freight.

It is recommended to keep the shipping container in case you need to pack and ship your propeller for any reason in the future.

What are the advantages of using an all-composite (no wood core) propeller?

Propellers constructed of all-composite materials without a wood core offer certain enhancements over the conventional wood core propellers such as:

- A more accurate propeller blade

- A more durable propeller blade

- A lighter propeller system overall

What is the core made of?

Our composite blade is solid in some areas and hollow in others. Primarily it is solid toward the tips and the root of the blades, and hollow in the center area.

What is the purpose of the very wide chord in the aerobatic propeller (200C and 400C Series)?

The wide chord allows for the low-end thrust required by serious aerobatic flyers. The wide chord allows the propeller system to really pull you through taxing maneuvers.

Do you make propeller systems for pusher planes?

Yes. Our 150 / 151 Series three blade propeller system is available in a 73" diameter pusher configuration. Please contact Whirlwind Aviation to discuss your specific requirements.

What is the life expectancy of the Whirl Wind propeller?

With a properly maintained and serviced propeller system you can expect an unlimited life for your propeller. This requires it to be serviced on a regular basis and does not include abnormal occurrences.

I've been told not to fly through the rain with a composite or wood propeller. How does the Whirl Wind hold up?

The Whirl Wind propeller is constructed of materials that are extremely durable and should not limit your airplane in any kind of weather. The nickel leading edge will provide superior abrasion and erosion protection over that of a wood or aluminum propeller and even a composite propeller with a stainless steel leading edge.

|